T5 or T8 LED tube? Differences, comparison & clear recommendation

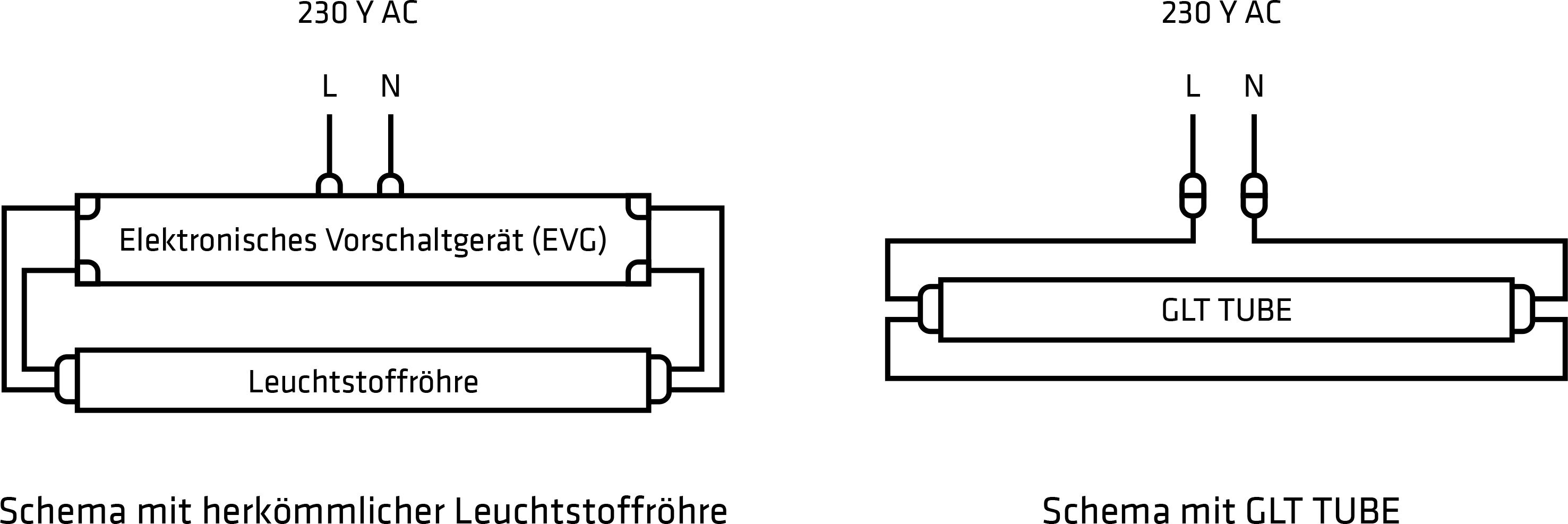

T5 tubes have an end cap for a G5 socket (narrow pin spacing), while T8 tubes are designed for a G13 socket (wider pin spacing). In fluorescent technology, T5 tubes could only be operated with electronic control gear (ECG).

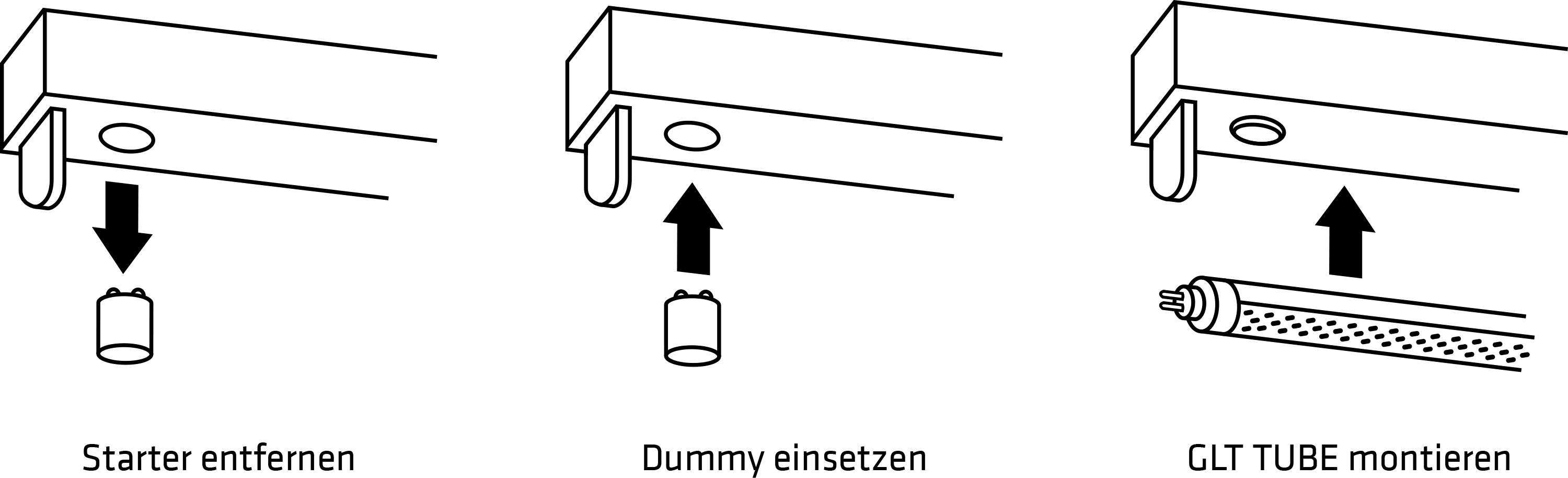

The existing luminaires and mounting systems determine the required length of the LED tube. GLT LED TUBES provide an ideal solution: a 1:1 replacement for all common sockets and lengths in accordance with IEC/EN 62776 – durable, efficient, and sustainable. This increases operational safety, reduces potential sources of failure, and enables maximum flexibility when selecting the appropriate LED tube.

130.000 h

service life

IEC EN 62776

1:1 replacement T5/T8

-40°C bis +70°C

industrial-grade

up to 80%

energy saving

Which LED tube replaces T5 or T8? Comparison & decision guide

Which LED tube (T5 or T8) replaces the existing lamp always depends on the installed luminaire. A luminaire or fixture with a G5 socket requires a T5 LED tube, while a G13 socket requires a T8 LED tube – always in the correct length.

Conclusion: The length and socket type of the luminaire (G5 or G13) determine which LED tube (T5 or T8) is suitable for a 1:1 replacement.

A lighting measurement also shows:

- how many light sources are actually required, and

- which colour temperature, lumen package, and wattage best replace your existing T5/T8 fluorescent tubes.

Common mistakes when replacing T8/T5 LED tubes

- Wrong tube type selected: T5 fits only G5 sockets, T8 only G13 – incorrect combinations are not operable.

- Key technical mistake: LED tubes without an integrated driver place load on the ECG, cause failures, and reduce efficiency.

- Compatibility ignored: Standards-compliant rewiring is mandatory for CE conformity, fire safety, and electrical inspection.

- Service life misjudged: Very low-cost LED tubes fail earlier and lead to higher total costs over time.

- Light colour & colour rendering overlooked: For good visibility and work quality, CRI ≥ 80 and the correct colour temperature are essential.

Overview of the most common mistakesOverview of the most common mistakes

Clear recommendations tailored to each application

More light. Lower costs. Better safety.

We plan your LED retrofit – standards-compliant and cost-effective.