IEC/EN 62776 standard – safely connect LED tubes directly to 230 V

IEC EN 62776 defines all technical and safety-related requirements that must be met when replacing double-capped fluorescent lamps (G5 and G13) with LED tubes in existing systems. The standard describes how retrofitting must be carried out correctly, which components need to be decommissioned, and how standards-compliant operation with an LED tube directly connected to 230 V is ensured. For companies, the standard provides a binding framework for continuing to use existing luminaires and fixtures while upgrading to an efficient, low-maintenance, and future-proof LED lighting system.

130.000 h

service life

IEC EN 62776

safety

EPD and ESG

conformity

up to 80%

energy saving

What does the IEC/EN 62776 standard regulate?

IEC/EN 62776 is the key product safety standard for the 1:1 replacement of T5 and T8 fluorescent tubes with LED tubes using the same bases (G5/G13). It covers the following aspects:

- electrical safety

- interchangeability

- permitted operating conditions

- mandatory temperature range between –20 °C and +60 °C

- test procedures under real operating conditions

Since 1 December 2015, the standard has been mandatory throughout the EU for all T5 and T8 LED retrofit tubes.

Objective of the standard:

The standard ensures that the transition from fluorescent lamps to LED lamps is carried out using safe LED products and under defined replacement conditions.

The standard distinguishes between two product groups:

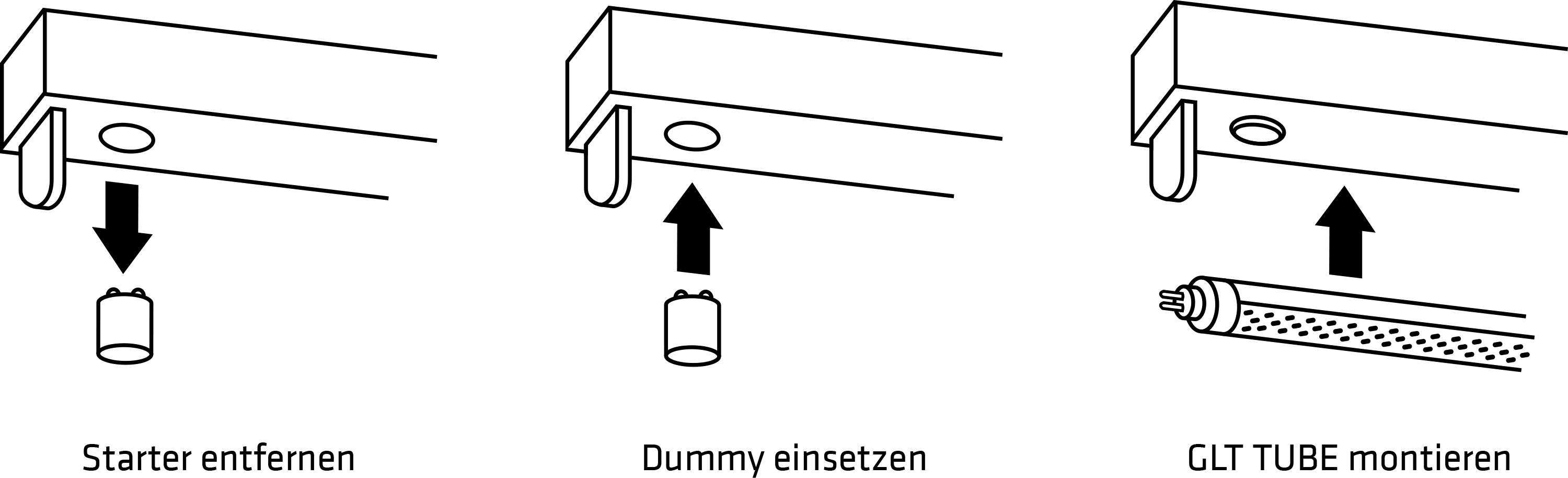

Double-capped LED retrofit lamp (for CCG/VVG luminaires)

1:1 replacement without modifying the luminaire. The starter is replaced with a dummy, electrically bypassing the CCG/VVG.

- No intervention in the luminaire

- Fast and easy renovation

- Operation directly at 230 V after conversion

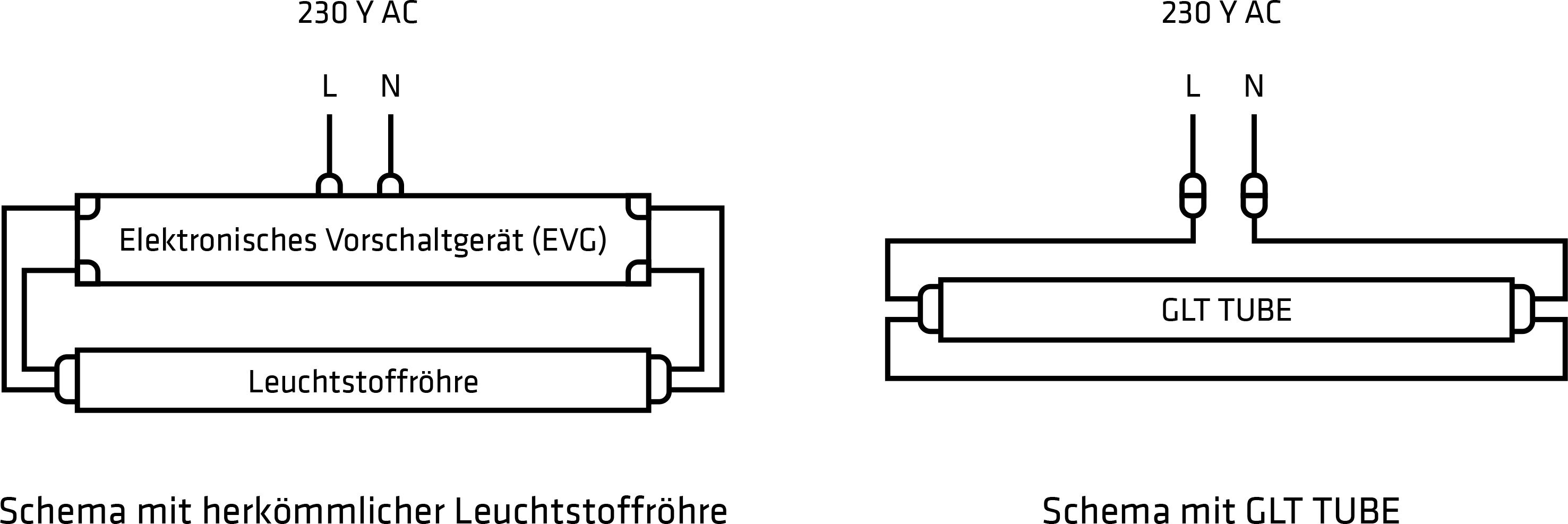

Double-capped LED conversion lamp (for ECG luminaires)

In this case, the ECG is converted in accordance with EN standards and the control gear is removed. The conversion must be carried out by a qualified electrician.

- ECG is decommissioned once by a qualified electrician

- Operation directly at 230 V after conversion

Why EVGs should be eliminated – LED tubes connected directly to 230 V

ECGs and CCGs originate from fluorescent lighting technology and are unnecessary for LED systems. They frequently cause malfunctions, energy losses, and failures. In a standards-compliant retrofit, they are bypassed; the LED tube takes over all functions via its integrated driver.

Weak points of external control gear

- switching cycles / flicker

- voltage surges

- uncontrolled start-up sequences

- additional power losses

- high failure rates

ECG conversion according to EN standards for G5 and G13 sockets without control gear

Advantages of direct connection to 230 V

- less electronics → fewer potential failure points

- lamp replacement without a qualified electrician

- no ECG losses → higher efficiency

- flicker-free, stable light

- standards-compliant retrofit according to EN 62776 and preservation of CE conformity

- decades of reliable operation based on an international standard

GLT LED TUBE – certified safety & sustainability (ENEC, EN 62776, EPD)

The GLT LED TUBE is the most reliable and sustainable LED retrofit solution on the market.

- ENEC-certified according to EN 62776, tested temperature range –40 °C to +70 °C

- Extremely long-lasting: 130,000 hours

- Up to 80% energy and CO₂ savings

- Fully integrated driver & surge protection

- EPD according to ISO 14025 – relevant proof for ESG reporting and CO₂ accounting

- GLT multi-use system and 90% recycling rate

Clear recommendations tailored to each application

More light. Lower costs. Better safety.

We plan your LED retrofit – standards-compliant and cost-effective.