FAQ

Here you will find answers to frequently asked questions regarding LED lighting. If you have any further questions, we are happy to help you by email or telephone.

FAQ about the GLT LED TUBE

LED retrofit list - which GLT LED TUBE replaces which fluorescent tube?

Standardized lengths

fluorescent tubes vs. GLT LED TUBEs

The lengths are standardized for straight fluorescent tubes (length without contact pins). GLT LED TUBE for LED retrofit according to IEC/EN62776.

What are the advantages of a GLT LED TUBE?

It reduces energy consumption and CO₂ emissions by up to 80%, is "Made in Germany," and is manufactured to the highest quality and environmental standards. With the longest service life and the highest quality on the market, it is particularly reliable. Thanks to its sustainable reusable system, the GLT LED TUBE is taken back, repaired, or recycled after use, reducing electronic waste and conserving resources. It complies with all relevant EU standards and is the only light source with an Environmental Product Declaration (EPD), which certifies its outstanding environmental performance throughout its entire life cycle.

What versions of the GLT LED TUBE are available?

The GLT LED TUBE is available in various versions to optimally meet different requirements. It is available in all standard lengths from 550 mm to 1800 mm and in various luminous intensities, offering different brightness levels as needed. They are also available in color temperatures of 3000K, 4000K, and 5000K. Different beam angles allow for customized light distribution depending on the application. Thanks to standardized interfaces according to IEC/EN 62776, the models are equipped with standardized bases and are therefore easily interchangeable. The GLT LED TUBE thus offers maximum flexibility and efficiency for a wide range of lighting requirements.

Can we use existing luminaires and fixtures?

Yes, you can usually continue to use your existing lights during the upgrade. The GLT LED TUBE is designed to be compatible with most standard light fixtures, making replacement simple and cost-effective. This saves you time and money, as no complex reinstallation is necessary.

Where is the GLT LED TUBE manufactured?

The GLT LED TUBE has been developed and produced exclusively in Germany since 2011. German LED Tech, a family-run company based in Aspach near Stuttgart, manufactures the lamps in modern, automated facilities under the highest quality standards. The electronics consist of 100% SMD components and comply with all relevant EU standards, including ENEC and EN 62776. Production takes place in compliance with strict environmental criteria, and the site is certified according to ISO 14001:2015.

Does the GLT LED TUBE comply with EU standards and norms?

Yes, the GLT LED TUBE complies with all relevant EU standards. It is certified according to IEC/EN 62776, meets current legal requirements, and has an Environmental Product Declaration (EPD) confirming its environmental compatibility and quality throughout its entire life cycle. They enable a future-proof, maintenance-friendly lighting system – completely independent of any manufacturer (no single sourcing). This allows you to remain flexible and independent.

Can we rent the GLT LED TUBE?

Yes, you can rent the GLT LED TUBE. This way, you benefit from fixed, predictable rental rates without high initial investments, conserve your liquidity, and save time and money by eliminating complex purchasing and administrative processes. The savings in operating costs usually fully cover the rental rates. This way, you maintain full cost control with maximum transparency.

Choose from various rental models to suit your needs. Starting from 12 months.

How long is the warranty on the GLT LED TUBE?

When you purchase, you receive a three-year warranty. When you rent, you benefit from a functional guarantee that applies for the entire rental period – including planning, retrofitting, and maintenance. Light as a Service from GLT offers comprehensive support with no hidden costs or risks.

How can we make a valuable contribution to sustainability?

Save up to 80% energy and CO₂ – permanently. The GLT TUBE is "Made in Germany," is recycled through a reusable system, and reduces electronic waste. As the only light source with an EPD (Environmental Product Declaration), it offers verifiable environmental performance over its entire life cycle – ideal for sustainable construction according to DGNB, LEED, or BREEAM.

What is the GLT take-back system?

At the end of the GLT LED TUBE's service life or rental period, the GLT LED TUBEs are taken back, repaired, or the raw materials are recycled. This actively contributes to reducing electronic waste and conserving valuable resources.

When you purchase a new GLT LED TUBE, you will receive a refund of €5 per unit when you return your old GLT LED TUBE. This return system is unique in the LED market and promotes the sustainable use of lighting technology.

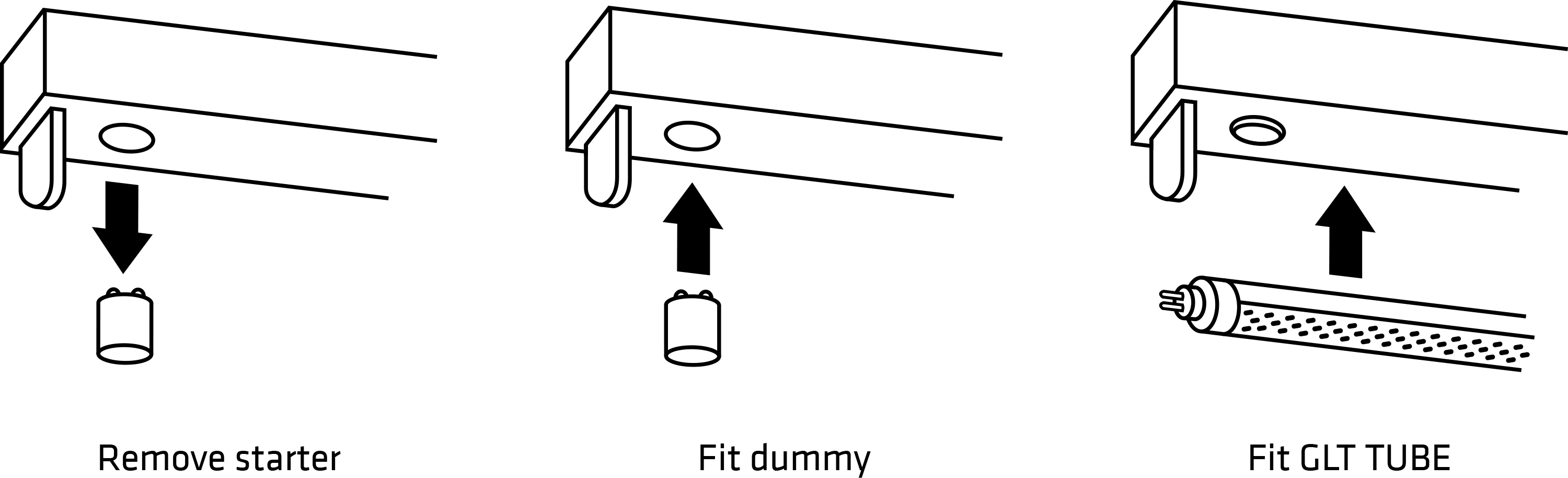

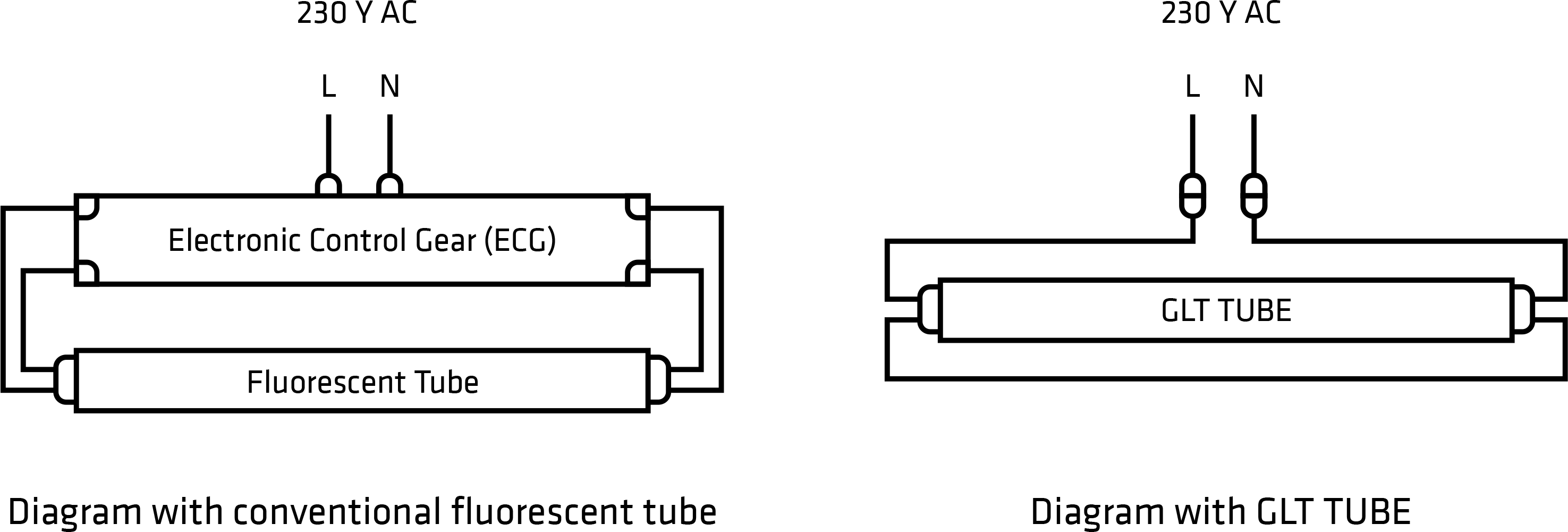

How do I convert to a GLT LED TUBE with a conventional ballast?

For fixtures with a conventional ballast, replace the starter with a dummy. Then install the GLT LED TUBE in place of the old fluorescent tube.

How do I convert to a GLT LED TUBE with an electronic ballast?

The installation of a GLT LED TUBE into an electronic ballast fixture must be performed by a specialist. Thanks to the direct power supply of the GLT LED TUBE, the interference factor of a ballast is eliminated, increasing operational reliability.

FAQ about GLT LED HIGH BAY

LED retrofit list GLT HIGH BAY: Which GLT HIGH BAY is suitable as a replacement for which HQL lamp?

Standardized HQL lamps vs. GLT HIGH BAYs

For 1:1 replacement (LED retrofit) of high-pressure mercury vapor lamps (HQL)

Can I simply replace my existing HQL lamps or spotlights 1:1?

Yes. The GLT High Bay Beam series was specifically developed for the safe and efficient 1:1 replacement of old HQL lamps or conventional spotlights – without major installation effort and with standardized connection options.

Is the GLT HIGH BAY suitable for high altitudes?

Yes. With a luminous flux of up to 40,800 lumens, a luminous efficacy of approximately 170 lm/W, and selectable beam angles (60° narrow beam or 90° wide beam), the GLT High Bay is ideal for high-ceilinged halls in industrial, logistics, or exhibition halls.

Do I need new wiring for the upgrade?

No. The GLT HIGH BAY is supplied as a plug-in light source and can be connected directly to the existing power supply. No additional wiring is required, which significantly reduces installation effort.

How long does the GLT HIGH BAY last and what is the warranty?

The service life is approximately 100,000 operating hours (L70), ensuring very long service life with consistent light quality. German LED Tech offers a 5-year manufacturer's warranty on the GLT HIGH BAY.

Is the GLT HIGH BAY protected against dust and moisture?

Yes. With an IP65 protection rating, the luminaire is dustproof and protected against water jets. An integrated pressure equalization membrane also prevents the formation of condensation.

How much electricity can I save with the GLT HIGH BAY?

Compared to conventional HQL lamps, the GLT HIGH BAY can save up to 80% energy.

Are there any funding options for converting to LED?

Yes. Converting to energy-efficient LED lighting can be supported by government funding programs, particularly within the framework of energy efficiency and climate protection initiatives.

Can I rent the GLT HIGH BAY instead of buying it?

Yes. German LED Tech offers the option of using the GLT HIGHH BAY on a rental basis. This allows companies to benefit immediately from energy savings and receive full service throughout the entire contract term – without any investment costs.

FAQ GLT LED FIXE Rail system und fixtures

What is a standard LED rail light system?

A standard-compliant LED rail lighting system consists of modular support rails and luminaires suitable for LED retrofit with LED tubes according to IEC/EN 62776. Such systems are particularly suitable for offices, industrial halls, warehouses, production facilities, and parking structures because they offer high energy efficiency, a long service life, easy installation, and low maintenance.

What are standard-compliant fittings such as damp-proof luminaires?

Standard-compliant fixtures, such as damp-proof luminaires, meet specific protection classes (e.g., IP65 or higher) and are designed for use in damp or dusty environments. Unlike complete luminaires, they can be equipped with various light sources and offer flexibility in maintenance and replacement. They are designed for LED retrofit according to IEC/EN 62776.

For which hall heights is GLT FIXE suitable?

The GLT FIXE system is designed for different hall heights. By using various LED light sources, the lighting can be optimally adapted to ceiling heights from 4 to over 10 meters. Typical applications include logistics centers, production halls, warehouses, parking structures, and offices.

Can I replace my existing T5 or T8 fluorescent tubes directly in the existing track systems or luminaires with the GLT LED TUBE?

Yes, the GLT LED TUBE enables a one-to-one replacement of T8 fluorescent tubes in existing rail systems or luminaires, provided they comply with the standards. For conventional ballasts (CCG), only the starter needs to be replaced with a dummy. For electronic ballasts (EB), rewiring should be performed by a qualified electrician.

Do I need new new rails or can I continue to use existing ones?

If your existing rails comply with standards and meet the technical requirements, they can generally be reused. An inspection by our experts or a consultation can provide clarity and identify any necessary adjustments.

How complex is the installation of the GLT FIXE system?

Installation of the GLT FIXE system is simple and time-saving thanks to tool-free click-in assembly. The components are clicked directly into the mounting rails, enabling quick and effortless installation.

How much energy and CO2 do I save with the GLT FIXE in combination with GLT LED TUBE compared to light strips?

By using the GLT FIXE system in combination with the GLT LED TUBE, energy savings of up to 80% can be achieved compared to traditional fluorescent lamps. This not only leads to significant cost savings but also significantly reduces CO₂ emissions.

Is the GLT FIXE system eligible for funding?

Yes, the GLT FIXE system is eligible for funding in combination with the GLT LED TUBE. Thanks to its EPD certification and ESG compliance, it meets the requirements of many federal and state funding programs.

How sustainable is the GLT FIXE system with GLT LED TUBE – and what certifications are available?

The system is characterized by its high level of sustainability. The GLT LED TUBE is EPD-certified, 90% recyclable, and features modular repairability. This supports the circular economy and reduces the ecological footprint.

What happens if individual modules are defective?

If individual modules fail, they can be easily replaced without shutting down the entire system. This minimizes downtime and maintenance costs.

Does GLT offer support with planning or installation?

Yes, German LED Tech offers comprehensive planning and installation support. Our certified installation partners and planning tools are available to ensure the efficient and standards-compliant implementation of your lighting project.

FAQ GLT LUME Cleanroom lighting

How does the conversion work with the GLT LUME Cleanled conversion kit?

The existing lamp carrier plate is removed from the cleanroom enclosure and replaced with the GLT LUME conversion kit. This is connected directly to the existing supply line and integrated into the enclosure. This maintains the IP protection rating, completes the conversion in just a few minutes, and the cleanroom remains enclosed.

Can I continue to use existing cleanroom lights?

Yes. The existing cleanroom housing will be retained, and only the electronic components (power supply and LED modules) will be replaced. This significantly extends the service life of the existing luminaires while conserving materials and resources.

Do I need a new cleanroom certification?

No. Since the existing enclosure remains unchanged and the conversion kit is integrated into it, the cleanroom certification remains fully intact.

What are the advantages of the conversion compared to a new complete luminaire?

With the GLT LUME conversion kit, you significantly reduce installation time, investment costs, and downtime. You only replace the components that actually need replacing, while the existing housing remains intact. This not only saves you costs but also conserves valuable raw materials.

For which cleanrooms is the GLT LUME conversion kit suitable?

Thanks to its high light output and outstanding efficiency, the conversion kit is suitable for both traditional cleanrooms in laboratories, pharmaceuticals and medical technology, as well as for higher cleanrooms, such as those required in aerospace.

What happens if individual LED modules are defective?

Individual modules or components can be replaced at specific times. Upon request, the conversion kit can also be sent in for re-equipment – without causing dirt or contamination in the cleanroom. This keeps maintenance simple, predictable, and cost-effective.

Does German LED Tech offer support with planning or installation?

Yes. German LED Tech supports you from planning to implementation. We manufacture the GLT LUME Cleanled conversion kit in the required sizes according to your requirements and, upon request, also handle professional installation – directly by our team or through certified GLT installation partners.